Welding an exhaust flange is common in automotive repair and performance work. Doing it right ensures a strong, leak-free seal that can handle heat and vibration. This guide explains the steps, methods, and key things to watch for.

What is an Exhaust Flange?

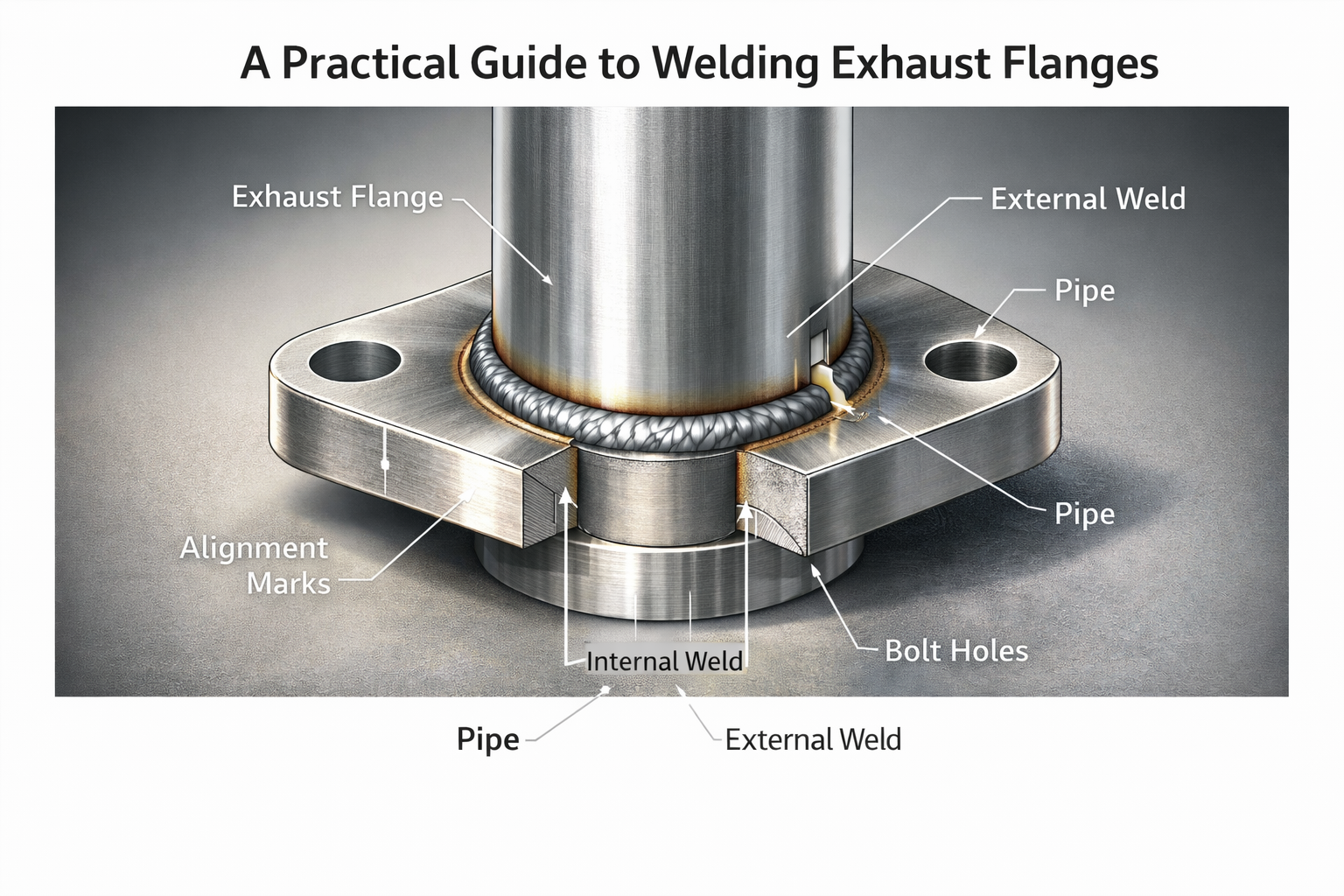

An exhaust flange is a metal connector that joins two sections of the exhaust pipe. It usually consists of two flat plates that bolt together, compressing a gasket in between to create a seal. This design allows for disassembly for maintenance. The most common types are flat 2-bolt or 3-bolt flanges, and circular V-band clamps.

For a strong weld, the flange material should match the pipe material. Common choices are mild steel for standard builds and stainless steel for better corrosion and heat resistance.

Key Steps for a Successful Weld

Good preparation and technique prevent common problems like leaks, warping, and cracks.

1. Preparation is Critical

- Clean the Parts: Remove all rust, paint, and debris from the pipe end and flange surface.

- Achieve a Tight Fit-Up: The pipe must fit snugly into the flange hole with minimal gap. A poor fit is a main cause of weld defects.

- Consider Back Purging (for Stainless Steel): To prevent “sugaring”—a rough, oxidized weld interior—flood the inside of the pipe with inert gas like argon during welding.

2. Alignment and Tack Welding

Slide the flange onto the pipe and align it squarely. Use a level or bolt it to a mating flange for accuracy. Apply small tack welds at several points (e.g., every 90 degrees) to hold everything in place.

3. Choosing Your Welding Method

For exhaust work, the two main options are TIG and MIG welding. Here’s a comparison to help you choose:

| Feature | TIG Welding (GTAW) | MIG Welding (GMAW) |

| Best For | Thin materials, stainless steel, and high-quality, precise welds. | Faster welding on thicker materials; easier to learn. |

| Control & Precision | Excellent. Allows for precise heat and filler metal control. | Good, but less precise than TIG. |

| Skill Required | High. Requires good coordination. | Moderate. Often considered easier for beginners. |

| Typical Use in Exhaust | Preferred for custom headers and performance systems where appearance and quality matter. | Common for repairs and production exhaust systems. |

4. The Welding Technique: Manage the Heat

- Use a “Stitch” or “Pulse” Method: Instead of welding the entire circumference at once, weld a small section (1-2 inches), then move to the opposite side. This lets the metal cool and prevents the flange from warping.

- Control Your Speed: Move at a steady pace. Going too fast can cause weak, uneven welds. Too slow can burn through thin pipes.

- Employ a Heat Sink: For critical jobs, bolt the flange you’re welding to a second, scrap flange or a thick metal plate. This draws heat away and dramatically reduces warping.

5. Post-Weld Inspection and Finishing

Let the assembly cool naturally. Inspect the weld bead for cracks, holes, or “undercut” (grooves along the weld edges). Clean the weld with a wire brush to remove discoloration or slag.

Frequently Asked Questions

Q: Why do my exhaust welds keep cracking?

A: Cracking is often due to stress concentration. Common causes are a poor transition between the pipe and flange, or “undercut” in the weld bead. Using a stitch welding technique and ensuring a smooth internal flow path can help.

Q: Can I weld a stainless steel flange to a mild steel pipe?

A: It is not recommended. The different metals can cause galvanic corrosion and the weld may not be as strong. For the best results, match the materials.

Q: Is a gasket necessary if the weld is perfect?

A: Yes. The weld creates a permanent mechanical connection, but the gasket is what provides the actual seal between the two flanges when bolted together. Always use a new, high-temperature gasket.

Q: My flange warped and won’t sit flat. Can I fix it?

A: Prevention is key. If it’s already warped, you can try to machine the face flat again, but it’s often better to cut it off and re-weld a new one using proper heat control techniques.

Q: What’s the most important safety rule for welding exhausts?

A: Always work in a well-ventilated area. Welding fumes, including those from mild steel, are hazardous and contain substances that can cause cancer. Use a fume extractor or a respirator designed for welding, and wear all standard protective gear (helmet, gloves, jacket).

Conclusion

A good exhaust flange weld comes down to three things: perfect preparation, controlled heat input, and the right technique for the material. By taking your time and focusing on a tight fit and even heat distribution, you can create a durable connection that won’t leak or fail.

Need a specific type of stainless steel or custom flange for your exhaust project? Submit your requirements to our team for a quote: http://texasflange.com/lp12/